Versatile Lime Plaster

Arrcoat’s Versatile Lime Plaster is a series of three unique decorative plasters that offer various dimensions in key-utility based areas and surfaces. Their versatility comes in the form of their incredible play with light and textures. From Matt/Glossy or gleamy effect to 5 coats of various colours and textures that this material can create, it in itself depicts its diversity and impact.

Features

VOC & Adhesion

VOC & Adhesion

Test Method

VOC Content (ASTM D-3960): Nil

Result

Tensile Adhesion Strength (IS:15477-2004): 1.62 N/mm²

Inference

Zero VOC, excellent adhesion

Impact & Hardness

Impact & Hardness

Test Method

Forward Impact: 0.2 NM

Result

Shore D Hardness: 64,

Pencil Hardness: 5H+

Inference

Hard surface, moderate impact resistance

Scrub Resistance

Scrub Resistance

Test Method

ASTM D2486 – Standard test method fro scrub resistant of wall paints

Result

10000+ Cycles for VLP and Bee Wax

Inference

Excellent durability against scrubbing

Stain Resistance

Stain Resistance

Test Method

ASTM D1308 – Effect of Household Chemicals on Finishes

Result

Tea/Coffee: 5; Green Chutney: 5; Food Stain: 5; Tomato Sauce: 5; Oil: 3; Alcohol: 5

Inference

Excellent overall; slightly weaker vs. oil

Mould Resistance

Mould Resistance

Test Method

ASTM D3273 – Resistance to Mould Growth

Result

PP100: 10-10-10; PP200: 10-10-10

Inference

Highly mould-resistant

Mechanical Properties

Mechanical Properties

Test Method

Compressive Strength (ASTM C-109): 18 N/mm² (28 days),

Flexural Strength (ASTM C-580): 6 N/mm² (28 days)

Result

Water Retention (IS:2250): 93.8%,

Water-Powder Ratio: 0.48

Inference

Strong and durable

Fire Resistance

Fire Resistance

Test Method

ASTM E84: Class A

Result

BS 476 Part 6 & 7: Class 0

Inference

Superior fire protection

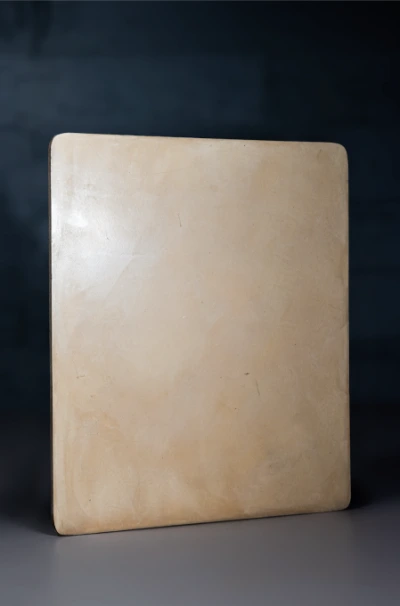

Our Finishes

From Base to Finish : ARRCOAT Guide

01

Product Overview

01

Product Overview

Arrcoat’s Venetian Plaster is a versatile decorative material made from finely blended plaster with dolomite, offering a matte effect that can also achieve glossy finishes with multiple coats. It allows for a range of effects, from subtle textures to high-shine surfaces, depending on application.

02

Surface Preparation

02

Surface Preparation

RCC / Cement Plaster

- Clean the surface and fix cracks or holes.

- Apply primer, then two coats of putty filler and one coat of acrylic putty.

- Sand, clean, and apply two to three coats of Venetian plaster, brushing between coats.

- Finish by sealing with BeeWax.

02

Surface Preparation

Plaster of Paris

- Clean the surface well.

- Apply one coat of primer.

- Apply two coats of acrylic putty, checking level each time.

- Sand and wipe clean.

- Apply two to three coats of Venetian plaster, brushing between coats.

- Finish with BeeWax.

02

Surface Preparation

MDF Boards

- Clean the surface well.

- Apply one coat of primer.

- Apply two coats of acrylic putty, checking level each time.

- Sand and wipe clean.

- Apply two to three coats of Venetian plaster, brushing between coats.

- Finish with BeeWax.

02

Surface Preparation

Gypsum Plaster

- Clean the surface well.

- Apply one coat of primer.

- Apply two coats of acrylic putty, checking level each time.

- Sand and wipe clean.

- Apply two to three coats of Venetian plaster, brushing between coats.

- Finish with BeeWax.

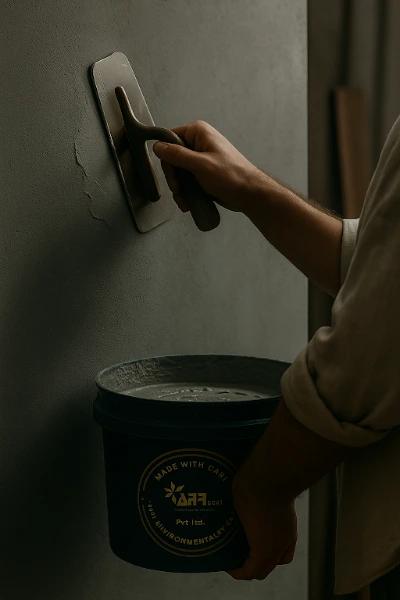

03

Application Steps

03

Application Steps

- 1. Start with a clean, smooth surface

- 2. Apply primer and putty for evenness

- 3. Sand after each coat

- 4. Finish with thin layers of Venetian Plaster

04

After Care

04

After Care

- Wipe with a soft cloth

- Avoid harsh chemicals

- Use pads under furniture

- Prevent scratches & stains

- Avoid water exposure & re-coating on damage