Marbleised Lime Plaster

This mixture is dug straight from the vast Indian subcontinent, now supporting nation-wide strong structures. With strong engineering, ARRCOAT’s polished plaster helps us get back our country’s lost glory in refined plastering.

Features

VOC & Adhesion

VOC & Adhesion

Test Method

VOC Content (ASTM D-3960): Nil

Result

Tensile Adhesion Strength (IS:15477-2004): 1.62 N/mm²

Inference

Eco-friendly (zero VOC)

Stain Resistance

Stain Resistance

Test Method

ASTM D1308 – Effect of Household Chemicals on Finishes (15 min open spot test, rating 1–5)

Result

Tea/Coffee: 3, Green Chutney: 3, Food Stain: 2, Tomato Sauce: 5, Oil Stain: 3, Alcohol Stain: 5

Inference

Good resistance to most stains

Scrub Resistance

Scrub Resistance

Test Method

ASTM D2486 – Standard Test Method for Scrub Resistance of Wall Paints

Result

10,000+ cycles (for PP100 and Aqua Wax)

Inference

Excellent resistance for scrubbing

Fire Resistance

Fire Resistance

Test Method

ASTM E84: Class A (Highly Fire Retarded)

Result

BS 476 Part 6 & 7: Class 0 (Will protect surface)

Inference

Excellent fire resistance properties

Impact & Hardness

Impact & Hardness

Test Method

Forward Impact: Measured in Newton-meters, Shore D Hardness (ASTM method implied)

Result

Impact: 0.34 NM, Hardness: 72 (Shore D)

Inference

Strong surface with good hardness

Our Finishes

From Base to Finish : ARRCOAT Guide

01

Product Overview

01

Product Overview

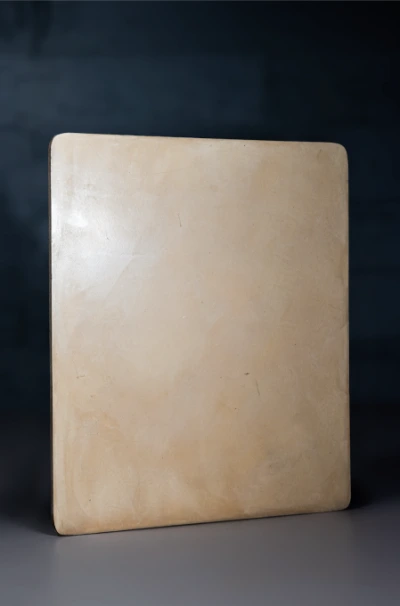

Arrcoat’s Marbelised Lime Plaster (MLP) recreates the timeless elegance of marble with natural lime and minerals. Versatile in finish: matte, satin, or glossy, it brings subtle veining, depth, and durable sophistication to walls.

02

Surface Preparation

02

Surface Preparation

RCC / Cement Plaster

- Clean the surface and repair cracks or holes.

- Apply coats of water-based primer.

- Apply polished plaster in thin layers, drying and cleaning between coats.

- Seal with AquaWax for durability.

02

Surface Preparation

Plaster of Paris

- Clean and dry the surface thoroughly.

- Apply 2 coats of water-based primer.

- Apply polished plaster in thin layers with a trowel, polishing the final coat.

- Seal with AquaWax.

02

Surface Preparation

MDF Boards

- Inspect the board for bulges, smudges, or wetness.

- Sand with fine-grit paper and apply 2 coats of primer.

- Apply polished plaster in layers, drying between coats.

- Seal with 2 coats of AquaWax.

02

Surface Preparation

Gypsum Plaster

- Clean and dry the surface.

- Apply primer or bonding agent.

- Apply polished plaster in thin, even coats, drying between layers.

- Seal with AquaWax.

03

Application Steps

03

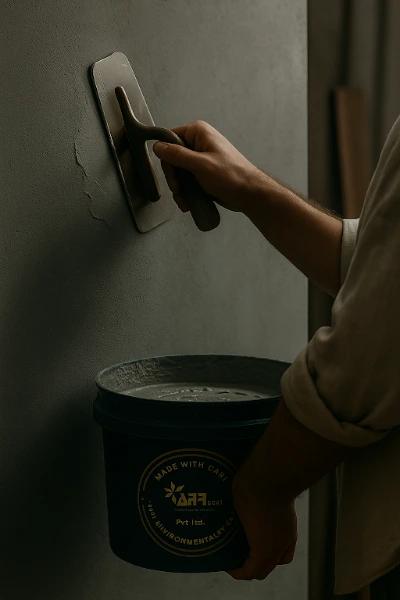

Application Steps

- Start with a clean, dry, even surface.

- Apply primer for strong adhesion.

- Mix plaster with colorants until smooth.

- Apply 2–3 thin coats of MLP, drying between coats.

- Finish by sealing with AquaWax.

04

After Care

04

After Care

- Wipe regularly with a soft cloth.

- Use only pH-neutral cleaners (avoid harsh or acidic chemicals).

- Prevent scratches with pads under furniture.

- Clean spills immediately to avoid stains.

- Avoid standing water; recoat if damaged.